Quality brakes built stronger

for accurate bends and hems.

POWERslot™ Hinge vs. Traditional Hinge

The question we are asked the most is, “What is the difference between the Mark I and Mark II?” The simple answer is color, but a more detailed answer is the hinge system. The Mark II TrimMaster® along with many other Van Mark brakes, are engineered with the POWERslot™ hinge that provide superior strength and allows for smaller hems. The Mark I Series™ includes a Traditional hinge that is ideal for doing fascia and covering “1x” with its’ “auto-measuring” ¾" distance. For more details, see below.

POWERslot™ Hinge

- 5/8" “auto-measure” bend ™ hem (hemming available on TrimMaster® & Metal Master® models)

- Ideal for fiber cement

- Strongest hinge available

The POWERslot™ was developed for two reasons: to increase the strength of the hinge and to allow smaller bends. The result was the POWERslot™ hinge that features a hollow core extrusion to provide unmatched strength and free-motion hinge that “auto-measures” at 5 ⁄ 8". The free-motion feature allows the POWERslot™ to keep a targeted, maximum pressure on the material throughout the entire bend while applying 100% of your leverage to the material for reduced effort. Comes standard on Mark II TrimMaster®, Mark IV Industrial TrimMaster®, Metal Master® 20, and Industrial Metal Master®.

Included on:

- Mark II TrimMaster® Contractor

- Mark II TrimMaster® Residential Heavy Duty

- Mark IV Industrial TrimMaster®

- Metal Master® 20 Contractor

- Metal Master® 20 Residential Heavy Duty

- Industrial Metal Master® 20

Need Tighter & Smaller Bends? Get a brake with POWERslot™

Traditional Hinge

- 3 ⁄ 4" “auto-measure” bend & hem

- Great for making pieces over “1 by”

- Ideal for making fascia pieces over 1x6

The Traditional Hinge has been a part of Van Mark’s DNA since 1964. Designed to be durable as a brick, the traditional hinge can require a bit more effort for hemming but will show its true strength in its simplicity, durability and its ability to “auto-measure” a ¾" bend. This bend makes this the perfect brake for covering fascia and other “1 by” lumber. Don’t waste time measuring a ¾" when the hinge will do it for you. Quick and easy.

If you are unsure if you get a Mark I Series™ or Mark II TrimMaster®, simply think about the types of bends you are going to make. If you don't need bends smaller than ¾" than a Mark I Series™ will be perfect. If you need to do bends smaller than ¾" and want a stronger hinge, than you should consider a Mark II TrimMaster® or Metal Master® 20.

Included on:

- Mark I Series™ Contractor

- Mark I Series™ Residential Heavy Duty

- Trim-A-Brake II™

20" vs. 14" Throat Depth

14" Throat Depth

The 14" Throat Depth was established early on as the standard for bending needs. The typical residential trim piece is around 8" in width, which is easily done with a 14" Throat Brake. If you are still unsure if a 14" Throat Brake is right for you, look at the material you are bending. If you are primarily using 24" coil stock, then a 14" throat depth will be perfect for everyday work.

Included on:

- Mark I Series™ Contractor

- Mark I Series™ Residential Heavy Duty

- Mark II TrimMaster® Contractor

- Mark II TrimMaster® Residential Heavy Duty

- Mark IV Industrial TrimMaster®

20" Throat Depth

The 20" casting was originally engineered to make the ultimate jobsite metal roofing brake, the Industrial Metal Master® 20. After customer demand from residential siding and roofing contractors, we created the Metal Master® 20 Residential. The immense strength of our 20" casting allowed us to include one less casting on a 10’6" compared to our Mark I Series™ and Mark II TrimMaster®.

Included on:

- Metal Master® 20 Contractor

- Metal Master® 20 Residential Heavy Duty

- Industrial Metal Master® 20

Residential vs. Residential Heavy Duty vs. Industrial

Deciding on the brake that is right for you and your job is all about your application. We have brakes for contractors who do primarily residential trim work. Brakes for contractors who are heavy in metal roofing. And brakes for contractors who find themselves somewhere in between. Before deciding, look at what material you are currently bending and what material you may bend in the future.

If you need help deciding what brake to buy, go ahead and call us at 800-826-6275

Contractor Brakes

The Contractor Series brakes are designed to be the most durable bending brake for the typical siding and roofing contractor. Engineered to repeatedly bend common trim around windows, doors, fascia and siding with soft aluminum with ease, accuracy and consistency.

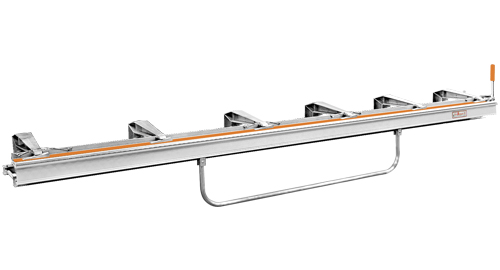

Industrial Brakes

Our Industrial Series brakes were engineered specifically for the metal roofing and metal architectural industries. We offer contractors the ability to fabricate material right on the jobsite. All Industrial brakes include a precisely engineered stand with platform to handle the load and strain from bending roofing metal.

Residential Heavy Duty Brakes

The Residential Heavy Duty Series brakes were introduced to help contractors who are bending various materials, like aluminum trim coil and up to gutter coil. These brakes will take heavy use and keep on bending.

Entry Level | DIY Brakes

Entry Level Brake for simple bends.